Imagine working on a construction site or in a warehouse, where workers need to reach high shelves or walls. How do they get up there safely with all their tools? Enter the scissor lift – a versatile work platform that can elevate people and equipment to various heights.

So, how does a scissor lift work? In this blog post, we will break down the mechanics and operation of scissor lifts. We will explore the inner workings that make these versatile machines so reliable and useful. Holdwell, a leading company in the manufacturing and supply of scissor lifts, offers insight into this fascinating topic. Let’s dive in and uncover the secrets of these powerful lifting machines.

Scissor Lifts Key Components

A scissor lift consists of several key components that work together to provide a stable and efficient lifting platform. Let’s take a look at these components and how they work:

Scissor arms

The heart of a scissor lift is the scissor arms. These scissor arms are typically made of high-strength steel to withstand heavy loads and frequent use. The arms form an interlocking X-shape, which gives the lift its name and unique vertical reach capabilities.

This X-shaped design is key to the lift’s stability. As the arms spread out, they push against each other to form a sturdy structure that can support a lot of weight. The interlocking nature of the arms also helps to evenly distribute the load, making the lift safer and more reliable.

Base

The base of a scissor lift is its foundation. It supports the entire weight of the lift, including the load on the platform. The base must be sturdy and stable to ensure safe operation.

Many scissor lifts also come with outriggers, which help to more evenly distribute the weight of the lift, especially on uneven or soft surfaces.

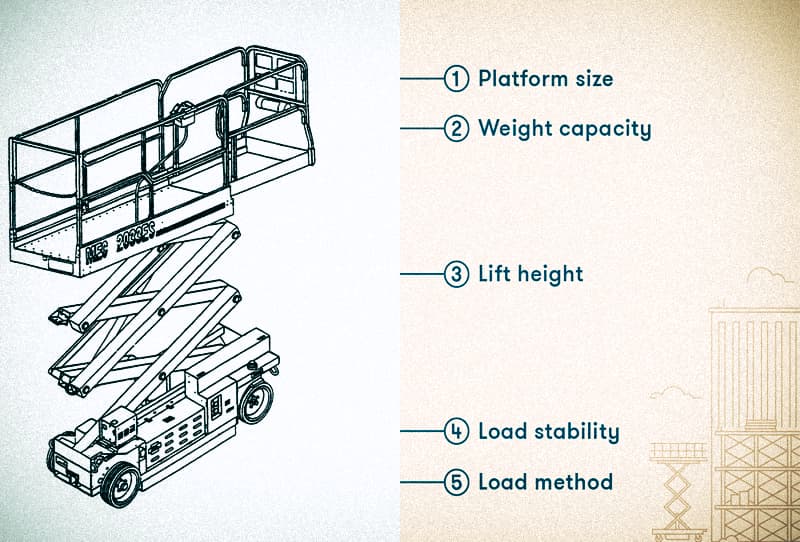

Platform

The platform is where the work happens. It’s designed with safety in mind, with a non-slip surface to prevent accidents. Most platforms also come with guardrails to prevent workers from falling. The size and design of the platform may vary depending on the specific application of the scissor lift. Some platforms may also include a tool tray or other accessories to assist with specific tasks.

How a Scissor Lift Works

The lifting process of a scissor lift relies on applying force to extend the scissor arms. This force can be created in a number of ways:

Hydraulic systems: They use fluid pressure to push a piston, which extends the scissor arms. As the piston moves, it forces the arms apart, which lifts the platform.

Pneumatic systems: Similar to hydraulic systems, but they use compressed air instead of fluid. The air pushes on a piston or diaphragm, causing the scissor legs to extend.

Electrical systems: An electric motor drives a screw mechanism or hydraulic pump. This action ultimately moves the scissor arms, which lifts the platform.

The heart of a scissor lift is its unique X-shaped design. The “scissors” are the crossed bracket arms, which give the lift its unique name. From the side, the arms look like a series of stacked Xs. When the lift is activated, the bottom set of arms begin to move apart. This pushing action forces the upper arms to extend, which raises the platform. As the arms extend, they create a mechanical advantage. This means that a relatively small force at the bottom can lift a heavier load on the platform. As the scissor legs extend, they push against each other. This pushing action causes the platform to rise vertically. The more the arms are extended, the higher the platform is.

The scissor design also helps to evenly distribute the load across all arms. This even distribution is essential to maintaining stability and preventing any one point from carrying too much weight.

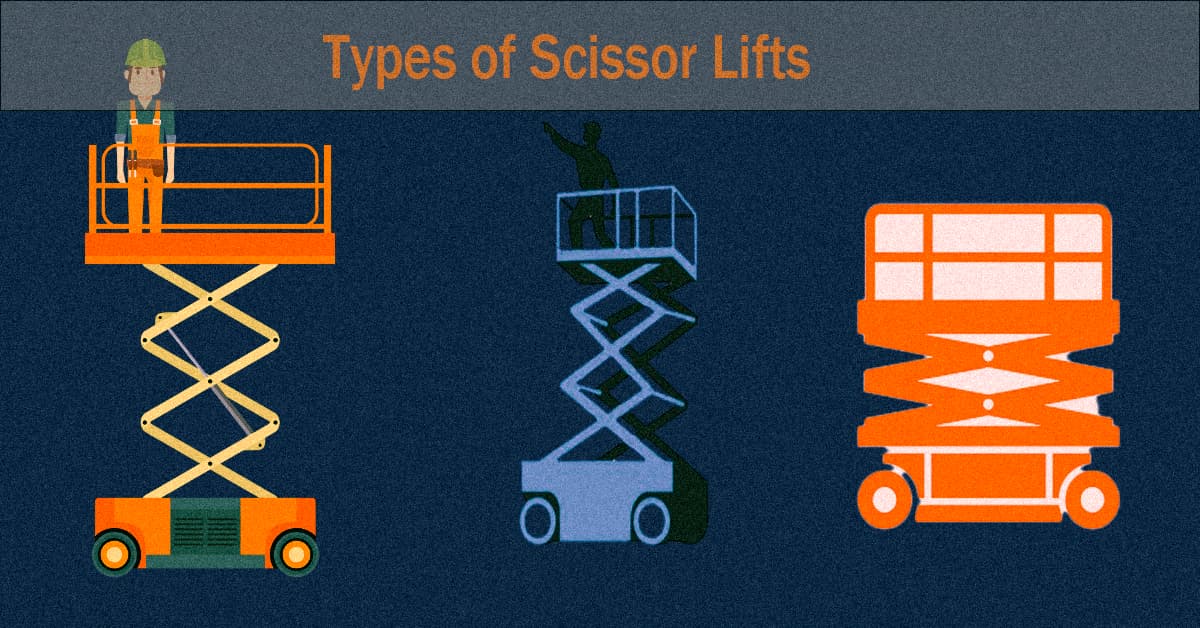

Types of Scissor Lifts

Electric Scissor Lifts:

These are powered by rechargeable batteries. They are quiet and emission-free, making them ideal for indoor use.

Diesel or Gas Powered Scissor Lifts:

These lifts use an internal combustion engine. They are better suited for outdoor use where electrical outlets are not available.

Rough Terrain Scissor Lifts:

These lifts are designed for uneven or challenging surfaces and have features like four-wheel drive and outriggers for added stability.

Advantages and Limitations of Scissor Lifts

Scissor Lifts Advantages:

Stability: The wide base and evenly distributed weight make scissor lifts very stable.

Compact Design:

When lowered, scissor lifts take up minimal space, making them easy to store and transport.

Variable Height: Users can precisely adjust the height to fit their needs.

Scissor Lifts Limitations:

Limited Horizontal Reach:

Scissor lifts can only move vertically, but have limited horizontal reach capabilities. This limitation can restrict tasks that require lateral movement. In contrast, boom lifts can extend outward.

Weight Capacity:

While most scissor lifts can handle a large load, their weight capacity is generally lower than other types of aerial lifts.

By understanding how scissor lifts work and their various types, you can better know how to use the scissor lifts. Holdwell sells used scissor lifts from all major brands. Whether you work in construction, maintenance or warehousing, these market-proven scissor lifts can help you work more efficiently and safely.